Production and Technology

Scanner-controlled optimizing system

Optimization is controlled with a Woodeye scanner. This system ensures best results when cutting out flaws and optimizing the raw wood material. Two undercut swinging saws connected at the output of the system satisfy highest performance requirements. The subsequent sorting and stacking line automatically handles the packaging of the optimized pieces.

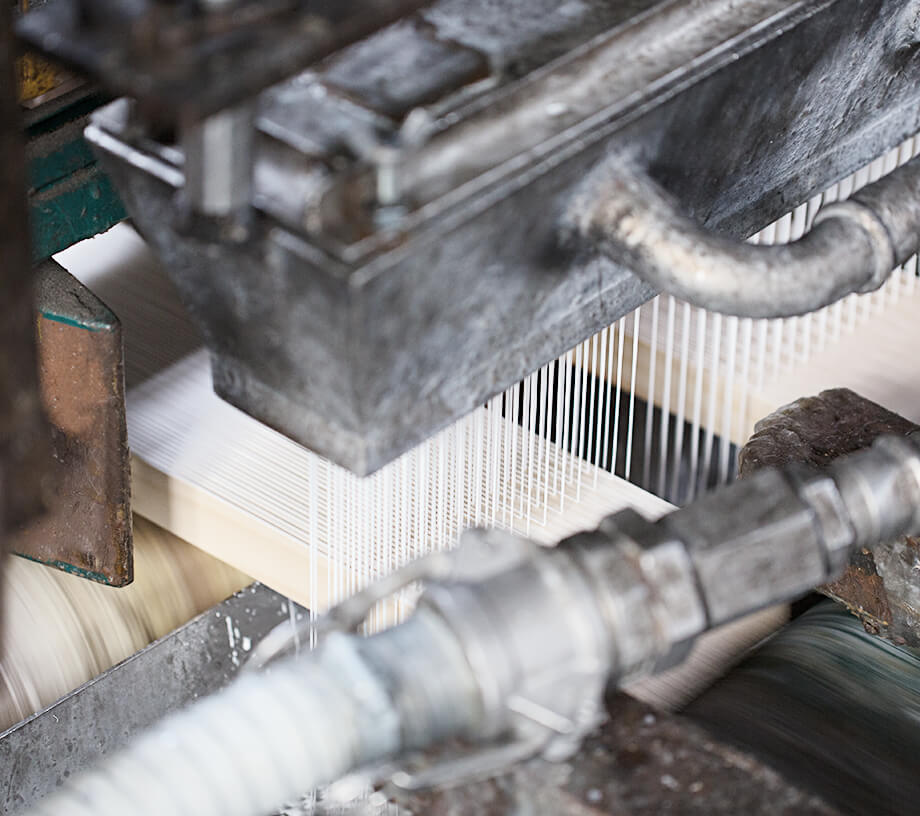

Wedge-finger jointing

In order to optimally use the raw wood material, two state-of-the-art wedge-finger-jointing machines, each with a twin milling station, process the short production remainders to make finger-jointed flawless wood lamellas suitable for intermediate plies or for cover plies to be paint coated.

Gluing

Time-tested lamination press walls offer best possible flexibility for processing dimensions and scantling structures. The capacity of the press is defined by a 32-metre-long pressing wall. Different glue systems can be used.

The section press

The section press satisfies the highest performance demands for standard scantlings Its highly-automated operation allows production without almost any intervention by operators.

Production of briquettes

All waste materials from production, such as chips and saw dust, are pressed to make high-quality wooden premium briquettes on three high-performance mechanical presses. They are packed in feed-through mode and piled ready for dispatch by a robot. This ensures that all production residues are used in an ecological way.